Industrial sectors

Contact Us

Business Cooperation

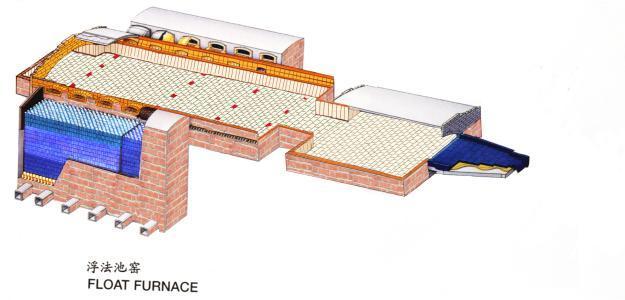

Float glass kiln

|

working principle

Maintenance and upkeep

Application area |

Products

Clay bricks are small building blocks made from clay as the main raw material, which are formed, dried, and baked. Clay bricks, also known as sintered bricks, are mainly made from materials such as clay, shale, and coal gangue, which are processed through a series of techniques.

The main uses of phosphate bricks include the cooling zone of cement rotary kilns, the main body of power generation boilers, lime kilns, zinc smelting furnaces, circulating fluidized bed boilers, electric furnace roofs, and rotary kilns in various industrial furnaces.

The corundum-mullite castable uses high-quality refractory materials, and the castable has good thermal shock resistance.

Zirconia sand is a mineral mainly composed of zirconium silicate, with ZrSiO4 as the main component. It has high melting point, high hardness, and excellent chemical stability, so it can still maintain stable performance in extreme environments such as high temperature and high pressure