Industrial sectors

Contact Us

Business Cooperation

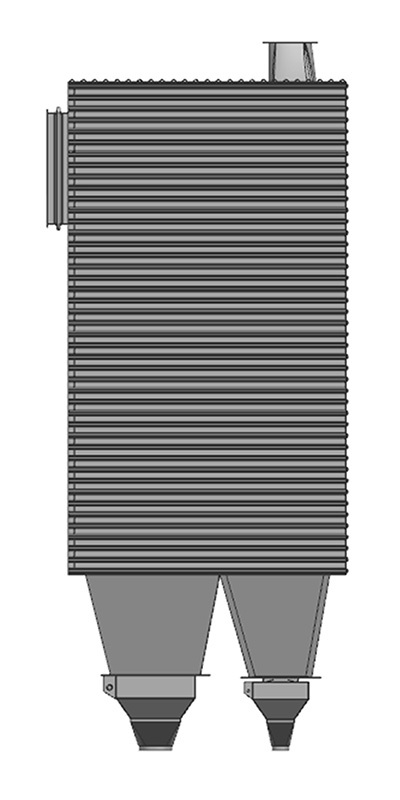

Heat recovery boiler(Waste heat boiler)

|

Working Condition Analysis

Refractory Material Requirements

Refractory Configuration |

Products

High Strength Alkali Resistance Brick

High-strength alkali-resistant brick is generally a refractory brick made on the basis of low aluminum clay bricks with Al2O3 content of 25 to 30%, adding silica, coke gems and appropriate additives to improve the compressive strength.

Corundum mullite brick is made of fused white corundum, high purity fused mullite, ultrafine powder and composite admixture by high pressure forming and high temperature sintering.