Industrial sectors

Contact Us

Business Cooperation

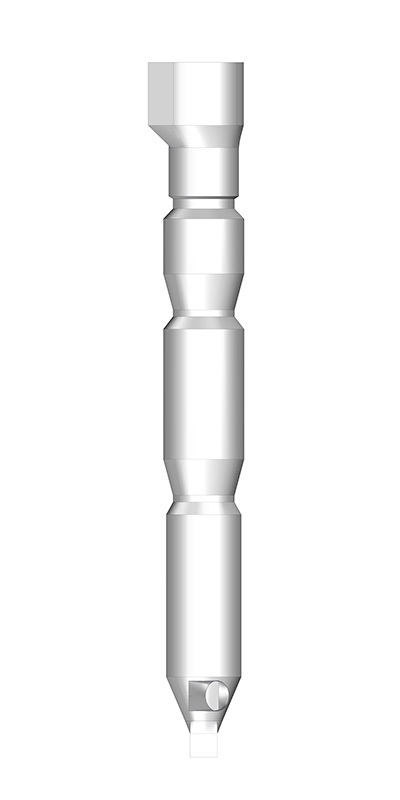

Decomposition Furnace

|

Analysis of working conditions

Refractory material requirements

Refractory Material Configuration |

General Properties

chemical analysis | sports event | Drop-resistant high alumina bricks | High strength alkali resistant bricks |

Al2O3 | ≥70% | ≥40% | |

Fe2O3 | ≤1.5% | ≤2.0% |

Physical property

sports event | Unit | Drop-resistant high alumina bricks | High strength alkali resistant bricks |

Apparent porosity | % | ≤22 | ≤20 |

bulk density | g/cm³ | ≥2.50 | ≥2.20 |

cold crushing force | MPa | ≥60 | ≥40 |

Refractoriness under load (T0.2 MPa). | ℃ | ≥1500 | ≥1350 |

chemical analysis | sports event | Lightweight castable insulation | Highly wear-resistant casting materials |

Al2O3 | ≥20% | ≥40% | |

Fe2O3 | ≤1.2% | ≥13% |

sports event | work unit | Drop-resistant high alumina bricks | High strength alkali resistant bricks | |

bulk density | g/cm³ | ≥1.40 | ≥2.35 | |

cold crushing force | MPa | 110°C×24h | ≥20 | ≥80 |

1100°C×3h | ≥20 | ≥100 | ||

modulus rupture | MPa | 110°C×24h | ≥4 | ≥12 |

1100°C×3h | ≥4 | ≥14 | ||

Reheat Linear Shift | (1100*3h) | ±0.5 | ±0.2 | |

Products