Industrial sectors

Contact Us

Business Cooperation

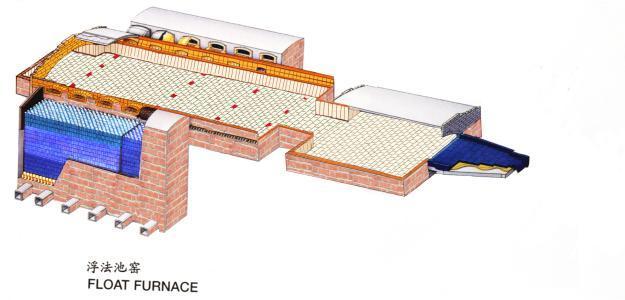

Float glass kiln

|

working principle

Maintenance and upkeep

Application area |

Products

Low Porosity Clay Bricks Octagonal Cylinders

Low porosity clay brick is made of high quality coke gem clinker, sintered mullite, three stone as the main raw materials by sintering at high pressure and high temperature.

Chrome Corundum Bricks (Octagonal Cylinders)

Chromium corundum brick is made of high purity electromolten chromium oxide and alumina powder, adding a small amount of zirconia, sintered at high pressure and high temperature.

Mainly used for supporting arches in the heat storage chamber of glass kilns and at the bottom of the melting pool, it features high temperature resistance, high compressive strength, excellent thermal shock stability, and superior high-temperature creep resistance.

Mainly used in the upper part of glass kiln regenerator chambers, small furnace walls, arch tops, molten pool tops, and feeding channels. It has characteristics such as high temperature resistance, good thermal shock stability, and low high-temperature creep rate.

Low porosity clay brick is made of high quality coke gem clinker, sintered mullite, three stone as the main raw materials by sintering at high pressure and high temperature.

Three lows" means low porosity, low iron and low creep. This brick is made of high-quality pyrophyllite, mullite and trilithon as the main raw materials, matched with composite ultra-fine powder and specific additives, and formed by high-pressure molding and high-temperature sintering. It has the advantages of high-temperature erosion resistance.