Industrial sectors

Contact Us

Business Cooperation

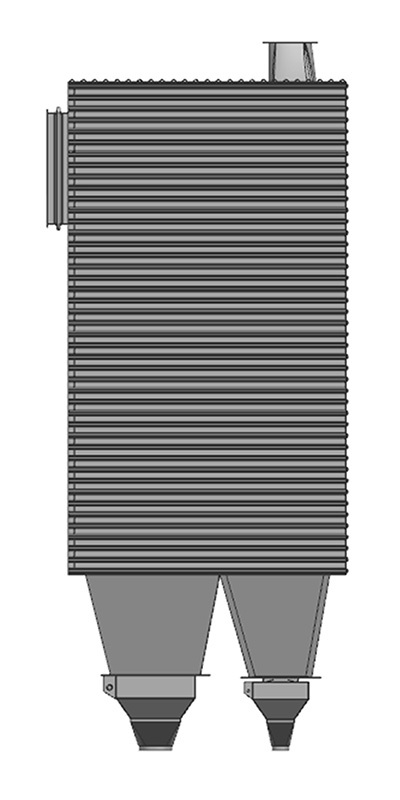

Heat recovery boiler(Waste heat boiler)

|

Working Condition Analysis

Refractory Material Requirements

Refractory Configuration |

Products

Specialized castables for kiln openings

The special castable for cement kiln is a high-performance refractory castable made of corundum, mullite, SiC, etc., which is combined with alumina powder and silicon powder and pure calcium aluminate cement.